VSDs vs. soft starters

Published: 06 October, 2021

Variable speed drives (VSDs) and soft starters provide ways to reduce the energy consumption of a motor by providing operators with solutions for control over their power. But which is the most appropriate choice? Marek Lukaszczyk* gives his advice for choosing a VSD or soft starter.

Solid state soft starters use semiconductor devices to temporarily reduce the motor terminal voltage. This provides control of the motor current to reduce inrush and limit shaft torque. As the name suggests, soft starters allow the motor to start the load more gradually by limiting the voltage to the motor and providing a reduced torque.

In addition to reducing energy consumption, a reduced voltage soft starter helps protect the motor and connected equipment from damage by controlling the terminal voltage. This limits the initial inrush of electrical current and reduces the mechanical shock associated with motor start up. By gradually increasing the motor terminal voltage the soft starter produces a more regulated motor acceleration up to full speed.

Soft starters are also capable of providing a gradual ramp to stop, where a sudden halt may create problems in the connected equipment

What’s a VSD?

As the name suggests, a VSD is a control device that varies the operating speed of a motor. A VSD, sometimes simply called a drive, inverter, or variable frequency drive (VFD), can control the speed of the motor during the start and stop cycle, as well as throughout the run cycle.

VSDs convert constant frequency and voltage input power to adjustable frequency and voltage source for controlling the speed of AC induction motors. VSDs allow for controlled starting, stopping and acceleration, as well as dynamic torque control during a motor’s operation.

Which to choose?

Choosing a soft starter or VSD completely depends on your application. Soft starters are smaller and less expensive when compared with VSDs, especially in larger horsepower applications. Larger VSDs take up more space and are usually more expensive than soft starters. However, while VSDs can be more expensive initially, they can provide significant energy savings, therefore providing operating cost savings over the life of the equipment for a lower total cost of ownership.

Speed control is another advantage of a VSD, because they offer consistent acceleration time throughout the entire operating range of the motor, not just during start up. VSDs can also provide more flexible functionality than soft starters offer, including digital diagnostic information.

That said, it’s important to note that VSDs can initially cost two to three times more than a soft starter. Therefore, if constant acceleration and torque control is not necessary, and your application only requires current limiting during start up, a soft starter may be a more costeffective solution

Soft starter applications

Soft starters are best used in applications where speed ramping and torque control are desired primarily when starting or stopping, or when a gradual controlled start is needed to avoid torque spikes and tension in the mechanical system. This could be relevant for conveyors, belt driven systems, gears, or couplings. Soft starters are also suited to piping systems that need to avoid pressure surges or ‘hammering’ when fluid changes speed up too rapidly.

VSD applications

VSDs are ideal for applications in which complete speed control is optimal. By providing customisable control, VSDs can reduce power when it is not required and increase it whenever it is needed. This is ideal for manufacturing applications in which equipment is used for multiple processes.

Consider a food processing facility as an example. On a production line that manufactures several types of products — requiring different equipment running at different cooking temperatures — a fan may need to continually adjust its power to provide optimal cooling. In this setting, an ability to adjust the fan speed provides an opportunity to save significant energy when compared to running the fan on full power continuously or turning it on and off multiple times per shift.

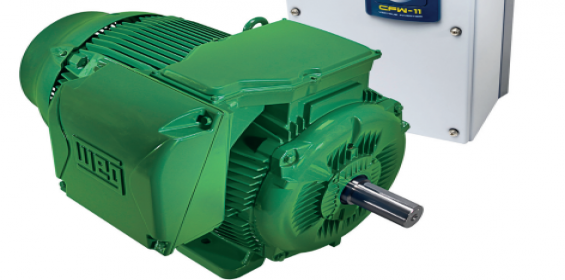

* Marek Lukaszczyk is European marketing manager at WEG Europe and Middle East

https://www.linkedin.com/company/weg-emena/

QUANTUM CONTROLS says it can provide 24/7 variable speed drive cover for any business for less per day than the cost of a cup of coffee.As a leading UK supplier of variable speed drives, motors and maintenance/repair services, Quantum has recently launched its newest service offering - The ‘One Call’ Contract.

QUANTUM CONTROLS says it can provide 24/7 variable speed drive cover for any business for less per day than the cost of a cup of coffee.As a leading UK supplier of variable speed drives, motors and maintenance/repair services, Quantum has recently launched its newest service offering - The ‘One Call’ Contract.