Software strategies

Published: 09 October, 2019

How much do you know about CMMS (Computerised Maintenance Management Software) or EAM (Enterprise Asset Management)? Maybe you have an existing system which nobody likes or possibly you are working with spreadsheets and paper and feel there must be a better way to manage maintenance within your company. Whatever your situation, you are likely to be working in one of the many maintenance departments that doesn’t have a clear picture of how to ensure CMMS/EAM software use is deployed and developed to maximise its potential benefit. Phil Taylor, associate consultant, MCP Consulting Group, reports.

There are many systems available today ranging in price from free to exorbitant and although most are perfectly capable of providing the functionality required for most maintenance operations many are damned as ‘bad systems’ with the most common reason cited for failure being a lack of “user-friendliness”. In truth, failed systems are generally caused by poor implementations and poor implementations stem from a lack of a clear maintenance software strategy.

The general structure of these systems has not changed significantly since their development from paper-based & T-card systems over 30 years ago. This structure normally includes the following elements or modules:

• Equipment

• Spare/replacement parts stock

• PPM (Planned Preventive Maintenance)

• Staff/contract resources

• Work order or job card planning/scheduling

• History

However the information and processes which make up the life blood of maintenance departments the world over include far more than these six elements. For example consider:

• Procurement • Energy isolation management

• Condition monitoring • Task Risk Assessment

• Reliability Centred Maintenance • Permits to Work

• Safety incident recording • Shift log

• Technical manuals • Technical drawings

• KPIs (Key Performance Indicators) • Reporting

• Contract management • Budget management

• Instrument calibration • COSHH (Control of Substances Hazardous to Health)

There are CMMS/EAM system suppliers who include some of the above in their offerings either as fully integrated functions or as modular additions which may or may not be integrated. More often than not however a maintenance department’s approach is to implement a basic CMMS and when additional functionality is required seek it from a specialist supplier, usually one which has had no involvement in the original CMMS supply or implementation.

A better approach is to develop a Maintenance Management Software Strategy. This can either be done at the outset for a new facility or as part of a strategic review for existing operations.

So what needs to be considered for such a strategy? First and foremost a software strategy must be aligned to a strategy for managing maintenance. There are many definitions of “Strategy” e.g. Johnson and Scholes in their book “Exploring Corporate Strategy” which gives the following:

"Strategy is the direction and scope of an organisation over the long-term: which achieves advantage for the organisation through its configuration of resources within a challenging environment, to meet the needs of markets and to fulfil stakeholder expectations".

A maintenance management strategy will therefore consider how the department should operate in order to provide the business with a level of OEE (Overall Equipment Effectiveness) to meet long term business objectives at the lowest cost associated with acceptable levels of safety and environmental impact.

Why use software?

Answering this question can help in developing a strategy. If we understand the ways in which software can be of benefit this can help quantify the value its use can add to an operation.

Maintenance of equipment requires experienced staff. Usually there is a premium to be paid for skilled technicians and they are employed to perform technical tasks such as carrying out preventive maintenance or repairing equipment which has broken down. Productivity can be as low as 50% with contributing factors including:

1. Searching for technical information or drawings

2. Single skilled technician waiting for a colleague with additional skill

3. Awaiting spare parts

4. Awaiting authorisation

5. Travelling to/from work site

6. Information management (updating computer records, drawings etc.)

7. Sickness

While the key to minimising time spent on item 1 is well organised data, the volume of data available these days is such that, no matter how well organised hard copy records are, software can still retrieve the information faster provided the level of organisation is similar or better.

Increasingly, companies are investing in multi-skilling maintenance technicians, which reduces inefficiencies from item 2. The point however is that good planning is essential in ensuring efficient use of staff. This also applies to item 5, travel time. Planning requires regular recalculations which can be undertaken more speedily with software than pen, paper and a calculator. Trial amendments to plans become far more practical when detailed calculations can be performed by a specially written algorithm.

Maintaining stock levels at a pre-determined level does not require software but computerisation can speed up repetitive processes such as processing stock requisitions and printing purchase orders. In addition, providing accurate stock requirement data has been entered into planned preventive maintenance tasks, computers can project stock utilisation levels much more accurately thereby allowing more of a ‘just-in-time’ approach to stock control maintaining stock holding costs at a minimum.

Where permits to work are used, formal authorisation to proceed is a significant element in the process and, while this can be organised to minimise any delays for planned work, significant time can be spent searching for authorisers for unforeseen events such as breakdowns or changes to pre-authorised schedules of work. While phones and pagers enable swift contact to be made, there is a need for an authorisation to be recorded in a way which can be audited at a later stage and time can be lost as requester and authoriser locate one another to ensure a signature is obtained. Some companies are now accepting electronic authorisation as an acceptable alternative to hand written signatures thus allowing time to be saved without reduction in safety.

As any maintenance software will require technician time to update data, it is essential that such time is kept to the minimum consistent with benefiting all concerned.

Finally, while a computer cannot prevent staff non-attendance due to sickness, it can help with reorganising depleted resources within short time frames.

To recap - software generally helps save time by locating information quickly, performing routine tasks efficiently and executing complex calculations accurately and speedily.

These benefits need not only apply to technical staff productivity. Consider regular production of KPIs for example. It can take clerical staff (and how often is this skilled technical staff?) significant time compiling statistics from manual records while with the correct software they can be produced & updated automatically making them available on demand. If a new analysis of data is required this takes minutes rather than hours as data retrieval from modern databases is quick and simple.

So how does knowing the benefits of software help in producing a Maintenance Management Software Strategy? It’s unlikely that budgets will stretch to buying maintenance management software to cater for all the department’s needs in one go so some prioritisation will be required. The functions selected for early implementation will be those which fit with the maintenance management strategy and provide the biggest efficiency savings. A value analysis of this sort can only be produced with an understanding of the various cost-saving mechanisms offered by software in general.

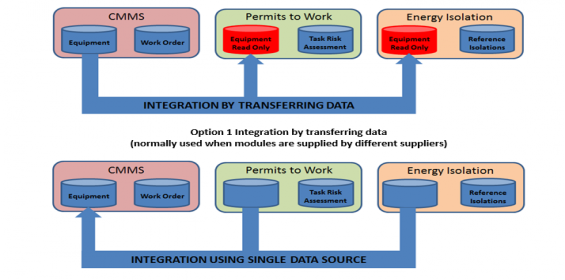

Integration

As a maintenance management software strategy will take a long-term view, it is necessary to consider how later software modules will need to interact with existing or initial software implementations. Integration can, if properly applied, save time duplicating data entry and provide solid reference points to tie information from different systems together for reporting purposes. Unless software modules scheduled for later implementation have been designed to integrate seamlessly with existing or initial software, integration is likely to be an expensive process and so benefits should be substantial or integration ruled out as a requirement.

Implementation

Many managers underestimate the length of time needed to implement a software module properly. Implementation stages include:

- Business Process Mapping

- Data collection and database population

- Software installation and configuration (only configuration if using SaaS)

- Staff training

- Trial runs

- Go-live & follow-up reviews

The above assumes there are no software modifications included in the process as this would add specification production, time for software development, factory acceptance tests and site acceptance tests thereby lengthening the process considerably.

Depending on the complexity of the software and the nature of its effects on business processes implementation can take anywhere between a few months to a year or more. Data is a significant element and much depends on the level and quality of basic data needed and available to populate the database. A green field site relies heavily on data provided by construction contractors and/or equipment suppliers which often requires effort to check and ensure quality is good – the alternative is the more time consuming manual process. Upgrading an existing system however can be relatively quick in comparison so long as data quality is good, as extraction and import is a simple matter with problems restricted to compatible field sizes and data types.

Staff training should also not be underestimated. The success of all software implementations relies on staff involvement which in turn demands good communication and training in the lead up to software introduction. Even with good staff cooperation there will be a period of inconsistent use requiring management input to instil new ways of working until they become automatic.

Finally, never fall into the trap of thinking the project is over once the system is live. Software usually has many more features than can be sensibly implemented at a single stroke. Some features will never be of any use to a particular operation but others will be good candidates for introduction once the system’s use has settled down over a period of time.

Producing a Maintenance Management Software Strategy

There is an old saying maintenance engineers often refer to, “If it ain’t broke don’t fix it”. The American Management Consultant Clark Crouch has adapted this slightly saying: “If it ain't broke, break it, then fix it. Otherwise you may be destined to address tomorrow's problems with yesterday's solutions.”

He is also credited with the drier but apposite: “Strategic Planning is a process by which we can envision the future and develop the necessary procedures and operations to influence and achieve that future.”

Maintenance Management software modules can be highly productive tools or unjustifiably expensive burdens on a workforce. The difference between these two extremes is strategic planning. Strategic planning is not difficult. It requires effort to understand the subject in its broadest sense and the ability to think in overview rather than in detail. The key steps in producing a Maintenance Management Software Strategy are:

- Identify how maintenance is currently being administered and managed

- Describe a vision of how maintenance is to be administered and managed in the future

- Know which maintenance disciplines can be helped by software

- Understand how software can be of benefit

- Determine if integration is appropriate and if so how much

- Calculate the cost benefit of each module

- Produce a prioritised list of software required

- Assess the time required to implement each module

- Determine the steps required to achieve the vision

- Align the maintenance software strategy with the company’s maintenance strategy

By considering each of these steps the strategy practically writes itself. It is as much about the journey as the destination and a strategy is only the first stage in changing things for the better but as the Chinese proverb says, “even the longest journey begins with a single step”.