Explosion proof lifting for hazardous environments

Published: 30 July, 2024

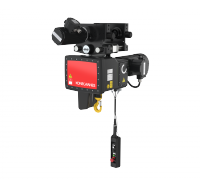

Lifting equipment specialist, KONECRANES, has announced it has launched its range of EX C-series electric chain hoists, engineered for explosion proof lifting in hazardous environments. The models are suitable for a wide range of industrial applications where gases, flammable substances, dust and other ignition sources create the potential for explosions. The EX C-series electric chain hoist has been designed and tested specifically to fulfil ATEX and IECEx requirements for use in Zone 1, 2 and 21 explosive environments.

EX C hoists offer inherently safe workplace operation. In addition to their explosion proof characteristics the models feature a slipping clutch which activates automatically providing protection in the event of an overload. They also incorporate a travelling limit switch and geared hoisting switch. Ingress protection is rated at IP66.

Ergonomics, operational efficiency, versatility and ease of use have been the driving factors in the development of the hoists. The compact design and low headroom allow maximum use of available workspace. Inverter controlled trolley movement and 2-step hoisting facilitate smooth and accurate load handling with a lifting ratio of 6:1 for operational efficiency. EX C models are available with SWLs from 320 kg to 2,500 kg. As standard the ambient operating temperature is +5° C to 40° C with -20° C to 55° C available to order. A comprehensive range of options and accessories may be supplied allowing hoists to be tailored to specific applications.

Smart engineering techniques have been employed in the manufacture of the EX C-series with the use of Konecranes ‘Core of Lifting’ components, including a purpose-built motor, gearbox and controls.

Click here for the full release

t: 01295 676100

e: sales.uk@konecranes.com