Choosing the right valve for efficient steam temperature control

Published: 13 June, 2022

Kieran Bennett explains how to select the right valve for steam temperature control.

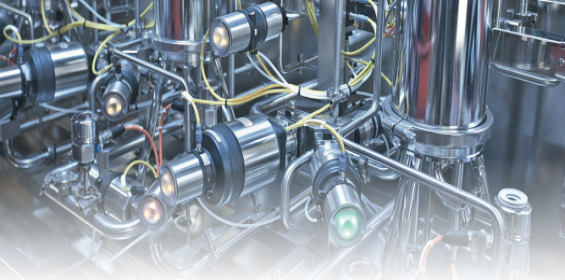

From beer brewing to cheese production, temperature control using steam is used across various applications in the food and beverage sector. The control valve is key, and precise specification is vital to optimise product quality and avoid production inefficiency. The choice of valve size and type is crucial to achieving these aims for effective steam temperature control.

While steam isn’t the only method for temperature control in food and beverage production, it’s used by many producers because it’s a very effective method of conveying heat energy. From mashing and wort boiling at a brewery to pasteurising milk and making cheese, steam is used by food and beverage manufacturers across a wide range of applications. Combined with a temperature sensor and a controller, a control valve is fundamental to a steam system to regulate the flow.

Cost saving through correct valve size specification

Ensuring that the right size control valve is specified is an easy way to make cost savings since a common problem is that excessively large valves are often specified. The larger the valve, the higher its cost, and operating expenses can also increase, requiring greater resources for actuation. The challenge of using over-sized valves can apply to new projects as well as existing installations, where often it’s incorrectly assumed that like-for-like replacement is the correct requirement.

On a recent project, a customer requested a replacement for a 40 mm valve for steam control. On initial enquiry with the customer, it emerged that the required valve was to fit 40 mm pipework. Unlike fluid control, the size requirement of a steam control valve will nearly always be a smaller diameter than its adjoining pipework. Also, as the original valve was installed over 15 years ago, advances in technology since then meant that in all likelihood a smaller valve could be used to achieve the flow and actuation requirements.

Further investigation of their application took into account the volume of product to be temperature controlled, the available pressure and the timeframe within which they wanted their product to be heated. Aspects such as the surface area of heat transfer were also considered.

Data returned from the calculations showed that a maximum valve size of 25 mm was required for the customer’s application, providing them with a cost saving from their initial request. For new applications, or the higher the number of existing valves to be replaced at a production facility, the greater the cost saving that can be achieved by correctly specifying valve size.

Increasing the accuracy and performance

Failure to correctly specify the size of valve for steam control can also impact accuracy and performance. For applications such as pasteurised milk production, accurate control is essential to ensure the right temperatures are met. Accurately achieving the required temperature gives optimum product quality, while inaccuracy and deviations can mean lower quality or ruined product with a higher cost of production.

If the configuration is too small, the valve has an inadequate flow reserve, recommended to be a minimum of ten percent, and therefore cannot offer the required control reliability or flexibility. Ultimately, if the valve is too small, it might not be possible to provide the desired flow rate and achieve the required temperature change.

Alternatively, if the valve size is too large, the system can face challenges maintaining the set temperature. With an over-sized valve, during heating it is nearly fully open, but to stop increasing the temperature and maintain the level, it has to be nearly fully closed. This way, an over-sized valve is too large to achieve the required precision, and temperature fluctuations result with an oscillating effect as the valve repeatedly attempts to compensate.

Choosing valve type

Where precision control of steam is required, a globe valve provides the greatest accuracy. While allowing a moderate flow of 13 m3/h, a globe valve ensures control accuracy to +/- 0.5 - 1.0 °C. In combination, Bürkert’s piston actuators for example, provide positional accuracy to within 0.1%, ensuring optimum control for steam and wider application types.

For some applications, this level of accuracy isn’t required. For example, at a particular dairy, steam is used in cheese production. The condensate from the boiling process is used to heat a secondary water supply for a staff washroom. The required temperature is approximately 60°C, but a difference of several degrees either way is not significant.

In a case like this, to save costs, a ball or butterfly valve can be used. Offering accuracy of +/- 5°C, which may be sufficient for more general temperature control purposes, a ball or butterfly valve provides full flow of 48 m3/h, which could be advantageous, depending on needs.

For hygienic applications however, where it’s a requirement for the media to be separated, a diaphragm valve should always be used. Bürkert provides stainless steel valves and actuators, robust and suitable for clean-in-place (CIP) applications.

In addition to the valve, the positioner, which is in-built on Bürkert valves, can also help reduce costs for steam control applications by taking load off the PLC. With a decentralised control concept, the Bürkert valve’s positioner receives the signal from the temperature transmitter and directly controls valve actuation. This way, the role of the PLC is reduced to monitoring purposes, meaning that for new applications a lower specification PLC can be used. For existing systems, the PLC’s spare processing capability can be used for additional tasks.

Regardless of the valve, actuator or positioner used, to optimise efficiency and performance in steam temperature control, the application has to be specified correctly at the outset. For a food and beverage production facility, it’s vital that your valve supplier provides this service.

* Kieran Bennett is Field Segment Manager, Hygienic-Food & Beverage at Bürkert

https://twitter.com/BrkertUKIreland

https://www.linkedin.com/company/burkertfluidcontrolsystemsuk&ireland/