H2 combustion technology is ready for the market

Published: 04 May, 2021

H2 combustion technology is ready for the market and offers a wide range of advantages - but there are some engineering challenges to overcome. PWE reports

In the public debate, hydrogen (H2) has advanced to become the energy carrier of the future, because its potential availability, especially in those industries that are difficult to decarboise, is enormous. The same also applies to heat supply, although at present it is mainly H2 from manufacturing processes that is used. A practical example at the specialty chemicals company Nouryon shows which technological hurdles have to be considered: To provide this cost-efficient, safe and low-emission use of the fuel requires specific combustion know-how.

The goal is ambitious: To become a climateneutral continent by 2050. The production of green hydrogen from renewable energies is expected to increase to one million tons by 2024 and to ten million tons by 2030. The infrastructure for transport and storage is already in place - up to 20% vol. H2 could be added to the UK natural gas grid in the future and these pipelines could thus be gradually converted. Infact, this figure of up to 20% is being looked at currently by a HyDeploy project hosted at Keele University. Whilst this initiative is a great step forward, to meet the 2050 target, 100% H2 needs to be looked at.

Currently, however, even the capacities permitted up to 10% vol. remain unused because not enough hydrogen is produced. In industrial heat generation, fossil fuels are often even cheaper or biofuels such as wood dust are an alternative. At present in the UK, there are several companies planning to use redundant energy from wind turbines for H2 generation, meaning the generation of energy from renewable forms will be maximised in the near future increasing utilisation and balancing the mix of the various types of H2 produced (grey or green) and also reducing the cost of the H2 production.

The political will for a climate-neutral hydrogen revolution is rapidly gaining momentum. This is because hydrogen is eminently suitable for thermal utilisation: In terms of fuel quality (Wobbe index) it is on a par with natural gas. Its calorific value, which is three times lower, is offset by its significantly lower density. Flame monitoring is also easily possible with existing standard UV flame sensors. However, despite all the potential in the use of H2 in heating processes, there are also a number of challenges to overcome. Smart combustion technology can contribute to efficient, safe and comparatively environmentally friendly operation as a piece of the mosaic - and not only as soon as the natural gas pipelines have been converted to hydrogen on a large scale, but also today for very specific applications.

Thermal utilisation of hydrogen as a waste product

The globally active company Nouryon was formed in 2018 from the chemicals division of the AkzoNobel Group and produces chemicals for everyday products. Max Krausnick, development engineer at SAACKE GmbH, explained that with the help of SAACKE, specialising in thermal processes and plants in the industrial and maritime energy management sector, the company has been converting its processes to H2 compatibility since the 1990s. This is because hydrogen is also produced as a main and surplus byproduct in the chlor-alkali electrolysis process at the European market leader for industrial salt, chlorine trading and chloromethanes. With plant upgrades such as the most recent one in 2019, these existing residual materials can be used as a valuable substitute and fed back to the heat demand of the electrolysis process instead of purchasing costly natural gas as the primary fuel. In this way, the operators - Nouryon operates the electrolysis in a joint venture with Evonik - not only anticipate legal regulations, but also use existing synergies and save 577 m3 of natural gas (H) per hour.

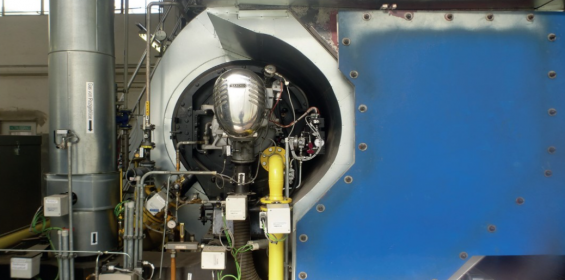

This is made possible by three hydrogen burners of the SKVGD type, which are based on rotary atomiser technology and are flexibly suitable for liquid and gaseous special fuels. In Ibbenbüren, they are installed with a maximum output of 4.3 to 7.6 MW (depending on the boiler size) on three steam boilers that generate superheated steam. However, they would be equally suitable for hot water boilers or thermal oil heaters. According to Krausnick, the specific requirements at Nouryon also led SAACKE to develop a standard H2 version of the SKVGD for a wide range of applications. The scope of delivery also included the SAACKE burner and boiler control system se@vis pro as well as a flue gas recirculation system with separate fan.

Exhaust gas recirculation

Despite all its potential, the thermal use of H2 requires some technological measures. Compared to natural gas, hydrogen produces three times as much NOx emissions, due to its higher adiabatic combustion temperature and approximately eight times higher flame speed.

Krausnick says SAACKE countered this problem with a sophisticated external exhaust gas recirculation system. This process ensures dilution effects and cooling of the flame by mixing inert exhaust gases into the combustion air. In this way, the emissions in Ibbenbüren in hydrogen operation can be brought into line with those of natural gas.

This means that the plant not only complies with the current legislation on emissions, but even falls significantly below these limits. This is because, depending on the intensity of recirculation, emissions drop further to about 40 mg/m3 @ 3% vol. O2 in the dry flue gas, even though a relatively high recirculation ratio is currently still necessary for this. NOx emissions as a function of the maximum recirculation ratio (RV) of the exhaust gas at Nouryon in Ibbenbüren (Source: SAACKE GmbH) Furthermore, the high H2 flame temperature also places special demands on the material.

SAACKE responded to this with heat-resistant steel and a special gas injection design. In addition, Krausnick explains that SAACKE experts have the pipe for the hydrogen feed flushed with nitrogen before the burner ignition in order to increase the safety aspect.

Automated control

Since the SKVGD burners can be operated variably with up to 100% pure hydrogen, completely with natural gas or in any mixing ratio and are also designed for operation with light oil as an emergency fuel, a special challenge arises: The performance-specific demand for supplied air as an oxidant differs significantly. Therefore, the SAACKE control system regulates the air volume depending on the fuel mix. The extremely low gas pressure of hydrogen (50 mbar(g) before entering the gas control line) requires the use of a special gas line with a particularly low pressure loss. For this purpose, a dynamic pressure probe was installed to measure the volume flow and softsealing flaps were installed as valves, instead of using commercially available turbine meters and quick-acting valves. The project example shows that the largescale thermal use of hydrogen, with industrial burners, is possible and available now.

Stephan Richter, head of technical service at Nouryon emphasised: “The hydrogen burners make an important contribution to reducing the CO2 footprint of our processes. SAACKE provided us with optimal support and advice on all questions and challenges relating to the project.“

For further information:

https://www.linkedin.com/company/saacke-combustion-services-ltd/