Modular cooling tower technology provide more cooling capacity

Published: 01 September, 2020

New advancements in modular cooling tower designs provide up to 50% more cooling capacity, greater energy and installation savings, fewer components and easier maintenance compared to other factory-assembled single-cell cooling towers. Scott Maurer* reports.

Recent developments in factory-assembled cooling tower technology are increasing the applications for so-called “package” towers supporting HVAC and industrial processes. Although field-erected towers have been preferred for power plants and industrial processes, today well-designed modular products suit a broader range of applications to simplify processes and positively impact their bottom line.

For example, an advanced design factory-assembled cooling tower can be delivered with 60% shorter lead time and installed up to 80% faster than what is typically estimated for building a traditional field-erected cooling tower. With no costly concrete basin construction required, simplified piping and electrical wiring, and flexible site placement, industrial processers more frequently consider the cost benefits of advanced factory-assembled towers.

Reducing energy and installation costs for HVAC applications

For HVAC end users who increasingly focus on reducing energy consumption, today’s new cooling tower designs specifically address energy efficiency. Using larger box sizes and low horsepower motors to meet these needs, advanced factory-assembled crossflow towers can offer up to 50% more cooling capacity per cell and use up to 35% less fan power per ton of cooling.

In addition to lower energy costs, these newer designs can also significantly reduce HVAC system installation costs. The increased cooling capacity per cell means customers require fewer cells, less piping and fewer electrical connections, minimising labor and material requirements. Safety hazards associated with long and complicated installation are minimised.

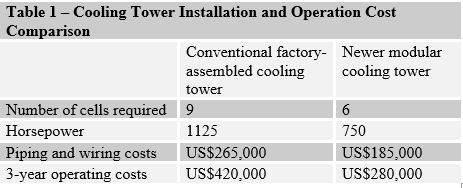

Table 1 compares installation and operating costs for a conventional factory-assembled cooling tower with that of a newer modular design in an HVAC project application. As shown, a typical cooling tower requires 1125 horsepower to meet the project’s cooling requirements. With three fewer cells, the newer tower requires only 750 horsepower to meet the same requirements and customers reap significant cost savings.

Reducing field-erection costs for process cooling applications

Cooling tower construction, cost and time management continue to be major concerns for those overseeing large process cooling projects. It can take 20 weeks or more for components on a typical field-erected project to arrive on site, involving large labor forces and expansive staging areas. Construction costs can easily mount and exceed estimates, and contractors often anticipate delays. The longer an installation project stretches, the more likely weather issues will impact completion. Complex industrial projects also heighten site safety concerns.

Industrial processors seeking alternative solutions are turning to pre-assembled cooling tower modules built in a controlled factory environment and shipped to the site in six to eight weeks. The installation process is carefully staged and managed, with up to 80% time savings compared to field-erected projects. The shorter delivery and construction times of pre-assembled towers offer industrial processing customers a distinct advantage because meeting capacity requirements and managing downtime and outages are critical to their operations. Additionally, their modular design and the field assembly process reduce onsite labor, work duration and lay-down area requirements, which contribute to the potential of a safer work environment.

Weighing the pros and cons of conducting a field-erected versus factory-assembled project, a customer recently received a construction estimate to replace a field-erected cooling tower, which called for 4500 hours and seven weeks of field labor. When a modular pre-assembled tower was specified, the construction team could reduce the installation duration to less than two weeks – an enormous savings in time and boost to the plant’s operational efficiency. The modular tower also eliminated the plant’s additional costs for temporary cooling during the construction process.

Building a field-erected cooling tower requires constructing a foundation in the form of a concrete cold water basin. The cost of this basin alone typically adds 40% to the tower construction costs. However, a factory-assembled tower includes an integral basin and eliminates the additional construction cost in field-erected projects. The accepted practice is to assemble and leak-test these integral basins in the factory.

Field-erected towers often require onsite testing to verify they meet the specified cooling capacity. Conducted by independent third-party agencies, the tests typically cost about $25,000. Factory-assembled towers eliminate these additional expenses because they are certified by the Cooling Technology Institute to meet thermal performance as specified.

Design advantages of new, pre-assembled cooling towers

Cooling towers with advanced, modular design are often constructed of heavy mill galvanised or stainless steel and engineered to withstand the demands of both HVAC and heavy industrial applications. If equipped with the latest in drift eliminating technology, these towers can achieve the lowest measurable drift rate, down to 0.0005% of circulating water flow, so less water escapes the tower. In addition, the broader market has demanded more features for convenience and easy maintenance. The newest designs make inspections and maintenance safer and easier. Some of today’s towers even include up to seven-foot high access doors and an expansive interior with service decks.

Cooling towers are typically designed to meet summer cooling demand. However, crossflow designs of modern, factory-assembled cooling towers permit “variable flow” operation, which reduces water flow rate and energy consumption during cooler months. This ensures energy is only expended for cooling when the plant truly needs it, maximising efficiency. By contrast, the counterflow design of many field-erected towers does not naturally allow changes in flow rate and uses the same amount of energy year-round, regardless of need.

Crossflow designs also shield cold water basins from sun exposure, thwarting algae growth that can compromise tower performance and call for more frequent maintenance. Additionally, in cold weather, a crossflow design helps prevent high winds from causing water escape, which can lead to icing and safety concerns.

Whether designing a cutting-edge cooling system or replacing a traditional cooling tower, carefully consider the latest technology and the best options for your application. Crossflow factory-assembled cooling tower designs are more frequently being tapped as the more efficient and cost-effective choice, especially as an alternative to more expensive and time-intensive field-erected construction projects, for an array of HVAC, process cooling and heavy industrial cooling applications.

Scott Maurer is a sales manager at SPX Cooling Technologies, based in Overland Park, Kansas.