Laboratory Eddy Current Separator

Published: 12 September, 2019

The University of Birmingham has purchased a laboratory-sized Eddy Current Separator and Drum Magnet modular system from Bunting-Redditch. Students and professors undertaking research at the university will use the new Metal Separation Module to determine the recovery and recycling capabilities of a wide range of materials. BUNTING says it is one of the world’s leading designers and manufacturers of magnetic separators and metal detectors for the recycling, quarrying, and mining industries.

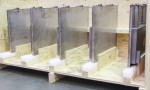

The laboratory Metal Separation Module comprises of a Vibratory Feeder, Drum Magnet and Eddy Current Separator. The Vibratory Feeder ensures an even feed of material feeding onto the high strength Drum Magnet. The Drum Magnet attracts and removes strongly and weakly magnetic materials. The remaining non-magnetic fraction falls onto the belt of the Eddy Current Separator.

e: press@buntingeurope.com

w: www.bunting-berkhamsted.com www.bunting-redditch.com

Click here for the full unedited version of the release as provided by the company

BUNTING MAGNETICS EUROPE, a leading supplier of magnetic separators and metal detectors, reports it has secured its largest single export order from a German processing plant designer and builder - the record order is to manufacture and supply 63, high-strength, Rare Earth Plate Magnets, which will be installed in a tobacco manufacturing operation in Indonesia.

BUNTING MAGNETICS EUROPE, a leading supplier of magnetic separators and metal detectors, reports it has secured its largest single export order from a German processing plant designer and builder - the record order is to manufacture and supply 63, high-strength, Rare Earth Plate Magnets, which will be installed in a tobacco manufacturing operation in Indonesia.