New immersive technology suites giving students a hands-on learning experience

Published: 20 August, 2024

The next generation of healthcare and engineering professionals are now being trained using the latest immersive technology following a £3million investment at Coventry University.

The university’s School of Health and Care has opened its new VR Cave Automatic Virtual Environment (CAVE) suite, while its College of Engineering Environment and Science has installed a Powerwall.

Funded from a £5million grant from the Office for Students, and supplied by Animmersion UK, the CAVE has a huge simulation screen wrapped around three walls on which different healthcare settings and scenarios are simulated, while students can also interact with simulated patients by using 3D headsets. The Powerwall is a floor to ceiling high-definition screen with 3D immersive technology allowing students to work together on projects using advanced visualisation tools.

The CAVE enables students to practice clinical events in a safe setting and put their learning into practice. They can zoom in on interactive organs such as the heart to better understand their structures and how they work, or interact with a healthcare mannequin connected to the screen.

They can practice patient interactions, treatment procedures, and diagnostic techniques specific to courses including diagnostic radiography, occupational therapy and physiotherapy.

Dr Natasha Taylor, Curriculum Lead for Healthcare Simulation at Coventry University’s School of Health and Care is an expert on simulation technology and has spearheaded several of the university’s projects in the area.

She said: “The CAVE is a totally immersive environment, it allows our learners at the touch of a button to move between environments such as a hospital ward, an operating theatre, the back of an ambulance or outside. We also have a model viewer that allows our learners to take parts of the body and look at them in depth, move them around and even go inside them.

“Simulation is threaded throughout all our curricula here at Coventry University, it’s a central pillar of what we do. It’s really important that our students can learn in a completely safe environment that allows them to make mistakes, and learn from their mistakes so when they go out into actual practice and see actual people they feel confident and competent. In our experience our learners really enjoy and benefit from simulation.”

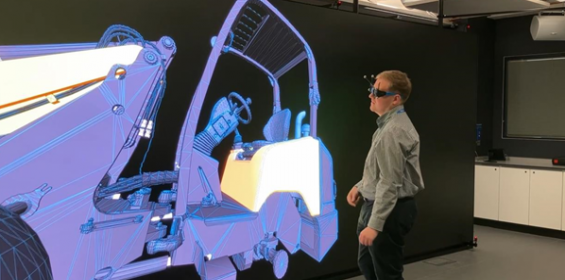

The Powerwall at the Beatrice Shilling Building also uses 3D immersive technology to help students better understand mechanical designs and projects they have created.

It allows them to display a design on screen and interact directly with it, allowing them to zoom in and see it from all angles. This can be used to help develop prototypes and will form a focal point for collaborative design sessions and discussions.

Hardeep Nandra, Technical Skills Advisor at Coventry University's College of Engineering, Environment and Science said: “This is a high capability, high-definition screen, capable of 3D imagery with tracking software which allows you to fully immerse with the screen itself. It gives students the chance to interrogate their designs, you can see right into the components and drawings, allowing learners to critique any areas that they might want to redesign. It’s an ideal tool for students in the department to use for their learning.”

Through an immersive classroom experience the Powerwall has the ability to transform and enrich student learning across many engineering subject areas. It provides a high quality stereoscopic immersive experience that is capable of taking students inside an engineering works, vehicle workshop, or construction site, or transporting them virtually to visit and study real-world locations anywhere on the planet.

Large groups of students have the ability to review designs and conduct interactive sessions, moving seamlessly from augmented reality factory simulations to component design optimisation.

https://www.linkedin.com/company/institute-for-advanced-manufacturing-and-engineering/