Aston University to shrink carbon footprint of industrial gas burners

Published: 22 May, 2024

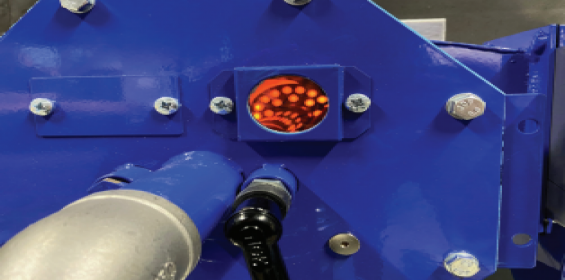

Aston University is working with an engineering company to make industrial gas burners more environmentally friendly. The University has entered a knowledge transfer partnership (KTP) with Lanemark Combustion Engineering to enable gas or propane burners users to reduce their greenhouse gas emissions.

A KTP is a three-way collaboration between a business, an academic partner and a highly qualified researcher, known as a KTP associate. The UK-wide programme helps businesses to improve their competitiveness and productivity through the better use of knowledge, technology and skills.

Aston University is a sector leading knowledge transfer partnership provider, with 80% of its completed projects being graded as very good or outstanding by Innovate UK, the national body.

Warwickshire-based Lanemark has been supplying industrial gas burners to sectors including petrochemical, car plants, breweries and food manufacturers for more than 40 years. The overall aim of the KTP is to help transition burners to use low carbon fuels such as hydrogen or biogas to meet new environmental standards.

Lanemark has developed their burner designs over several decades using different software applications. To calculate the impact of using new fuels either alone or in different mixes with propane or natural gas, Lanemark’s engineers currently have to transfer data between different software applications which is time consuming and inflexible.

Aston University will be sharing its expertise to create a single software package to calculate the impact of using different fuels and to integrate these into existing designs. The programme will analyse factors such as exhaust gases, flame length and heat transfer, and ensure equipment remains agile and competitive in a changing market

Aidan Lewis, technical manager at Lanemark said: “We are a relatively small company in our industry, so it’s important that we aren’t left behind by some of the bigger players. Having this new software will make us more agile in responding to new regulatory requirements and customer demands, which will keep us in a competitive position.”

Aston University will provide Lanemark with access to specialist research expertise in areas critical to low-carbon industrial heating systems, including heat transfer, heating systems, and burner design. Lanemark will gain the necessary skills and knowledge to maintain and adapt the software in the future as required, which is tailored to meet the specific needs and expectations of the company’s clientele.

The company is working with Aston University’s Dr Muhammed Imran from the Energy and Bioproducts Research Institute and Dr Martin Rudorfer from the School of Computer Science and Digital Technologies. Dr Imran is a senior lecturer in mechanical and design engineering, whose research focuses on developing innovative thermal energy systems and improving the energy performance of existing energy systems. Dr Rudorfer is a lecturer in applied AI and robotics, who has expertise in software engineering and intelligent automation of processes.

Together with KTP Associate Dr Tarun Kumar, the research team has been working to understand the requirements of the new software and how it will be used by different people within the company. This has enabled them to build the user interface for the software, which will allow design engineers, sales agents and customers to access the complex engineering that underpins the burner designs. The software is being built within a commonly used computational platform called MATLAB.

Lead academic, Dr Muhammad Imran said: “With fundamental research, impact can take a long time, but with a KTP, the outcomes are far more immediate. Not only will this collaborative research help Lanemark commercially, it will also significantly improve the carbon reduction potential for their products. To contribute to that is very satisfying, particularly as we will start to see the impact in just a few years.”

Dr Rudorfer added: “As researchers, sometimes it can feel we’re inside a research bubble and not really seeing our ideas and concepts being put into practice. My role as a computer scientist is to create the mechanism by which the engineering expertise from the University can be transferred to the company. It’s great to see how a KTP like this can really make an impact with local businesses.”

At the end of the project the team will provide Lanemark with detailed manuals to ensure they can use and adapt the software and algorithms as required.

https://twitter.com/AstonUniversity

https://www.linkedin.com/school/aston-university/

To obtain the precision required of many PLC flow control systems, Badger Meter has launched its next generation Smart Electric Valve Actuator (SEVA). The company says available through PUMP ENGINEERING, the actuator is built with military grade components to withstand extreme conditions while the microprocessor controlled linear stepper motor provides exceptional positional accuracy to give the reliability, accuracy and repeatability needed.

To obtain the precision required of many PLC flow control systems, Badger Meter has launched its next generation Smart Electric Valve Actuator (SEVA). The company says available through PUMP ENGINEERING, the actuator is built with military grade components to withstand extreme conditions while the microprocessor controlled linear stepper motor provides exceptional positional accuracy to give the reliability, accuracy and repeatability needed.