Education takes centre stage at SM&E Week

Published: 01 May, 2024

The live events for Smart Manufacturing & Engineering Week 2024 take place at the NEC, Birmingham on the 5th and 6th June. PWE looks into what visitors can expect at the event amid the myriad of activities taking place.

From 5-6 June 2024, the NEC Birmingham will transform into an epicentre of industrial innovation and connectivity, hosting the Smart Manufacturing & Engineering Week (SM&E Week).

Across its two halls, six exhibitions, two summits and eight education theatres, the event addresses the key issues that concern manufacturing and engineering businesses currently, irrespective of the market sector they serve. The main themes of the wide-ranging event are innovation, the supply chain, sustainability, digital transformation and people and skills.

Central to the week’s proceedings, Fluid Power & Systems and Air-Tech Exhibitions offer an unprecedented glance at the latest in engineering innovation. Co-located alongside Drives and Controls, Smart Factory Expo, Maintec and Design & Engineering Expo, this year’s event encapsulates the multifaceted nature of modern manufacturing.

The week is set to unfold under the banner of cutting-edge technology, with primary partners such as 3M, Abdex Hose and Couplings, Amazon RME, Binder, Charter Controls, Emerson, Festo, igus, ILME, Lutze, Pilz Automation, Teseo SRL, Tom Parker, Wurth Electronics, ETA Enclosures, Eriks, Jenny Science AG and SMC Corporation leading the charge.

Educational content & Summits

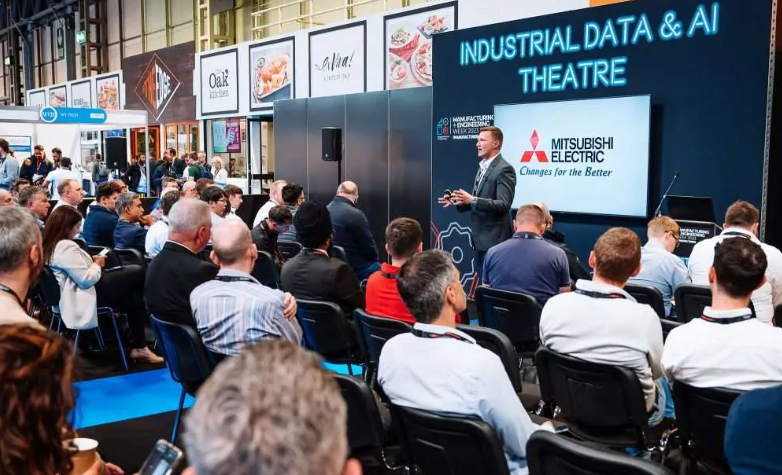

To those familiar with Smart Manufacturing & Engineering Week (SM&E Week) it will come as no surprise that education and peer to peer learning plays an important role. There are two summits that run alongside the exhibition namely the Industrial Data and AI Summit and the Manufacturing Digitalisation Summit.

Now in its 7th year the Industrial Data & AI Summit takes place on the 5th of June and focuses on Data Management and Data Insights. The structure of the summit includes four keynote presentations, a panel discussion and two 60-minute roundtable discussion sessions. The summit allows senior leaders to hear from the sector’s most respected experts, such as the Head of Digital and Data at BAE Systems and the Senior Director of Data and Analytics at Mars, as well as to share their knowledge and experiences with their peers. The roundtable sessions offer a unique opportunity for in-depth discussions on topics ranging from Data Integration and Management to Developing a Data Driven Business to Generative AI.

Taking place on both the 5th and 6th June at the NEC is The Manufacturing Digitalisation Summit. This summit includes eight keynote presentations, two panel discussions and four 60-minute roundtable discussion sessions. The Summit focuses on how digitalisation is changing how products are designed, produced, used and maintained as well as transforming the operations, processes and energy footprints of factories and supply chains. This summit is broken down into two distinct streams, the Enterprise stream is for those working within businesses with revenues in excess of £100 million while the Growth stream is for those less than £100 million (theoretically classed as SMEs)

While the summits charge an entry fee there is also a huge amount of free-to-access education during the event with no less than 144 presentations taking place across the eight education theatres. The theatres cover: Drives & Controls, Digital Transformation, IIoT & Connectivity, Industrial Data & AI, Innovation, Maintenance, Air-Tech Solutions and Fluid Power & Systems.

In the Fluid Power & Systems Theatre Colin Guttridge, Principal Manufacturing Engineer, Baker Hughes will be talking about Navigating the People and Skills Landscape in Manufacturing and Engineering whereas Dale Crow, Electricity & Automation Leader, Nestle will be covering Leveraging Technology to Maximise Functionality and Performance.

The BFPA will be providing several sessions including: Filling the Skills Gap and Offering Opportunity which will be presented by Chris Butcher, Managing Director of the BFPA. The Standards Development Process from Nicky Quinn, Standards & Projects Manager, BFPA who will explore the role standards play in facilitating international trade and improving product quality, safety and interoperability and finally the subject of Fluid Injection Injuries will be covered by Martin Kingsbury, Director of membership and Training, BFPA.

Also on in the Fluid Power Solution Theatre is a session from Colin Gutteridge of Baker Hughes who will cover: Navigating the People and Skills Landscape in Manufacturing and Engineering. Colin will look at topics from skill shortages to the imperative of diversity and inclusion and explore the critical aspects shaping the workforce dynamics in these industries because finding and retaining talent is a significant challenge for many manufacturing companies.

Elsewhere in the Air-Tech Theatre Alice Quinn, Senior Manufacturing Technology Engineer, 3M will be talking about Why IT/OT Projects Fail whereas Ioana Hera, Head of Improvement, Rolls Royce will be presenting on Harmonising People, Skills, and Technology: The Path to Manufacturing Innovation and Efficiency.

Also, in the Air-Tech Theatre Ahmed Kovacevic, Reseach Chair in Compressor Technology and Ivona Ivkovic-Kihic, Research Project Coordinator both from City, University of London will address: Energy Sustainability and Net-Zero for Screw Compressors. The talk will introduce the University and the Centre and concentrate on the recent projects called Smart Efficient Compression, Reliability and Energy Targets (SECRET) and the Industrial consortium for Compressors and Expanders in Future Energy Systems (CERES).

Additionally, Ahmed Kovacevic, Reseach Chair in Compressor Technology will present on the subject of: PDM Analysis Ltd, the creator and distributor of software SCORG for design and analysis of superior screw compressors and expanders. The software is used by most of leading OEMs in air and vacuum technologies, hydrogen compression, refrigeration, air conditioning, high temperature heat pumps, oil and gas and process industries.

Finally, on 6th June in the Air-Tech Solution Theatre Ioana Hera, Head of Improvement, Rolls Royce will talk on Harmonising People, Skills, and Technology: The Path to Manufacturing Innovation and Efficiency. This discussion aims to explore how organisations can effectively bring these elements together to drive innovation, optimise processes, and empower their workforce.

While the Drives & Technology Theatre will feature a series of compelling speakers from the world of industrial automation. On day one, David Santos, head of manufacturing engineering and automation at Chelton will start at 10.00 by talking about SMEs and Automation: Overcoming Complexity and Challenges During and After Implementation. The presentation will delve into the realm of digital empowerment, exploring how technology drives the evolution of external supply chains towards global excellence.

This will be followed by Jason Reed, machinery safety specialist at Pilz Automation, who will address the important topic of Keeping Machinery Safe in a Digital World at 11.00. He will discuss the challenge of ever-increasing cybersecurity threats and examine their potential impact on machinery safety functions, addressing the pressing concerns raised in the upcoming Machinery Regulation.

At 11.30, Josh Roberts from Festo will present on Selecting the Optimal Field-Level Machine Control Architecture. With his extensive experience in industrial automation engineering and business development, Roberts will act as a guide to choosing the right field-level control architecture to maximise machinery performance, efficiency and cost-effectiveness.

At 12.00, James Kinsman, technical director at Overview, will consider the topic: The Paradigm for Sensor Motion is Changing: Redefining Agility and Accuracy in Smart Sensors. As a driving force behind the innovative ServoTorq development program, he will unravel the key drivers revolutionising modern sensor systems, powered by AI, and the demand for real-time digital data.

Also happening on the first day, the Industrial Data and AI Theatre will feature a technical discussion at 13.00 that will include real data from robot applications including welding, aerospace drilling and additive manufacturing. Entitled How Iona improves Robot Performance and Why this is Essential for Modern-day Manufacturing, and presented by Craig Davey, COO at Insphere, this session is suitable for anyone working in robots and automation.

In another keynote presentation at SM&E Week, Neelofar Ansari, senior manufacturing engineer at BAE Systems, will be presenting on the intriguing topic of Human Augmentation: Connecting with Manufacturing Environments on (at 13.30 on 5 June in the IIoT and Connectivity Theatre).

Elsewhere, Emma Devereux, managing director at Maintech Recruitment, will address the difficult issue of How do we Combat the Skills Gap? She will give examples of companies that have tackled the problem head-on and others that have really struggled to recruit and retain staff (15.00 in the Maintenance Theatre).

To close proceedings on day one, Claire Bailey, head of data and analytics at Saffran Seats, will be talking about Data-Driven Culture: The Smart Way to Digital Success (15.30 in the Industrial Data and AI Theatre). She will delve into the challenges and solutions associated with implementing new technologies and securing senior leadership buy-in for data governance initiatives.

On the second day, Krishna Mistry, vice-president of series engineering at Verge Motorcycles, will kick off proceedings in the Drives & Technology theatre at 10.00 with a presentation entitled: Agile Engineering Cycles: Optimising Design, Development, and Deployment in Manufacturing. This will explore how, by integrating agile practices into design, development, and deployment processes, organisations can enhance efficiency, adaptability, and product quality.

In the Maintenance Theatre, Philip Dewson, head of maintenance and facilities at Brompton Bicycle, will deliver a presentation at 10.30 called Beyond Bolts and Bearings: Holistic Facilities and Maintenance Management and Impact on Culture.

At 11.30, Charles Wright, UK director of data and analytics at Columbus, will deliver a presentation in the Industrial Data & AI Theatre entitled: Simplifying AI Adoption in Manufacturing: A Product-Based Approach. In the rapidly evolving landscape of smart manufacturing, AI (artificial intelligence) has emerged as a pivotal force driving innovation and efficiency. However, the harsh reality is that up to 92% of AI initiatives stumble before reaching full-scale production. Charles, a seasoned expert in data strategy and AI, will demystify AI integration by presenting insights into how a simplified, product-based approach can vastly improve adoption rates.

In another keynote speech, Roy Haworth, head of digital mock-up process and implementation at Airbus Defence & Space, will be talking about Using CAD Data to Drive Data Fusion and 3D Visualisation (6 June at 12.00 in the Innovation Theatre). He will explore the ways that CAD data can be used to bridge the engineering-production gap.

In addition, at 13.30 in the Digital Transformation Theatre, Robert Clifford, head of digital and data at BAE Systems, will be presenting on The Three Horizons of your Digital and Data Strategy. The manufacturing sector is the latest domain to embrace the digital and data transformation ethos. However, developing an organisation’s digital and data strategy can often seem like a daunting prospect. This presentation will offer an overview of how to start small, move quickly and think big, progressing swiftly from the drawing board to implementation.

The full programme of keynote presentations and other sessions is available at: https://www.mandeweek.co.uk/educational-content-2024.

Visitors are encouraged to plan their programme in advance, and this can be easily done using the individual theatre exploration tools available on the Web site. There are eight solution theatres in total covering the topics of: Digital Transformation, IIoT & Connectivity, Industrial Data & AI, Innovation, Maintenance, Drives & Technology, Air-Tech Solutions, Fluid Power & Systems.

Learning and networking

As well as the summits and educational theatre sessions, there are other learning opportunities during the live events at the NEC on 5 and 6 June – for example, The Institute for Manufacturing (IfM), University of Cambridge Masterclasses. These interactive workshops are free to attend but places are limited and must be pre-booked.

Several events for The Manufacturer Directors’ Forum will take place during the week. This network of senior manufacturers is now more than a decade old with members, drawn from across the industrial spectrum, sharing knowledge by attending targeted events and roundtable discussions.

A major focus for Smart Manufacturing & Engineering Week is people (both young and older) and skills. The STEM programme includes support for the IMechE Apprentice Automation Challenge as well as its Formula Student Programme. Taking place in Hall 5, as part of Drives & Controls, is the Fanuc Industrial Robots Qualifiers which will see teams of two 16–20-year-olds competing in dynamic challenges that will test their ability to gather and apply information, work effectively in teams, follow instructions, and create robot programs. Visitors can also experience the excitement for themselves with an interactive Fanuc robot “try it yourself” session.

Also focused on people is the “Oscars” of the manufacturing sector – The Manufacturer Top 100. Held on the evening of 5 June, the programme provides a platform and a showcase to celebrate the best of UK manufacturing – not big businesses and household company names – but the inspiring people who make the industry tick. The Manufacturer Top 100 scours the length and breadth of the nation to find the 100 most dynamic leaders and innovators in manufacturing, nominated by the industrial community and judged by a panel of industry leaders, academics and manufacturing associations.

On the key issue of skills (and also taking place on 5 June) is The Enginuity Skills Awards organised by Enginuity, the charity dedicated to supporting UK engineering and manufacturing employers by finding new ways to close skills gaps and open opportunities. The awards recognise apprentices, pioneers of skills development, and innovative engineers who are passionately and diligently tackling some of society’s biggest challenges. Each year, leaders from the engineering and manufacturing industry across the UK gather at the Skills Awards to celebrate the finest talent and commend the organisations dedicated to advancing skills development to ensure a bright future for these vital sectors of the UK economy. This year’s landmark tenth anniversary of the awards is no different, making SMEW an ideal backdrop for the celebration.

The Skills Awards offers a variety of categories catering to areas ranging from Equality, Diversity, & Inclusion, to distinctions such as the Large and SME Employer Skills Champion awards, and the Training Partner Skills Champion award. In addition, the awards encompass accolades tailored to individuals committed to enhancing their expertise in the field, such as the T-Level Student award and multiple apprenticeship categories. Winners of both of these stand to gain a £1,000 prize, with two runners-up in each category receiving £500.

Notable organisations

A notable element of the planning for SM&E Week is the advisory council that the organisers bring together. The advisory council includes representatives from the event’s Strategic Partner organisations such as the British Manufacturing Consortium; The Centre for Compressor Technology; the iMechE; Engineering UK; GAMBICA; IED; BFPA; IFM University of Cambridge; The Manufacturer, Made Smarter. These organisatons collectively steer the educational element of SM&E Week, ensuring that presenters are addressing the crucial topics that people are interested in and in most cases, they have exhibition stands themselves so that they can talk to their members or answer questions from visitors.

The charity partner for SM&E Week is Engineers Without Borders UK, an organisation focused on ensuring that globally responsible engineering is taught as a principle on engineering degree courses and also used within industry.

Innovation

As well as giant tech businesses, SMEs and industry organisations one of the key themes is innovation. Many manufacturing-focused startups will be showcasing their ‘bleeding edge’ solutions in Innovation Alley which is sponsored by the HVM Catapult and Innovation UK and which literally runs right through the middle of Smart Factory Expo.

With so much innovation on show across all the events it’s difficult to pick out individual examples but two early disruptive technologies do catch the attention. Firstly, Insphere on Stand: 4-N73 is launching IONA, a scalable network of sensors that deliver metrology-grade positional data to automated manufacturing processes. The data is used to improve the accuracy and performance of industrial robots, including identifying and correcting errors in the production line.

Using IONA, manufacturers can make sub-millimetre corrections to robot positions and alignment with parts before mistakes are made. IONA enables a right-first-time approach, saving time, money, energy and reducing waste.

A second example on Stand: 4-D21 is Addition Design which has designed a new process that allows food manufacturers to access production parts that meet food safety requirements through additive manufacturing. The process extends Addition Design’s ‘AddParts’ service – which supplies digital spares for automated production lines using 3D scanning, digital data management and industrial 3D printing – into the food processing sector. The new technique addresses several issues that affect the industry’s ability to embrace the benefits of 3D printing while complying with food-safety regulations and production line efficiency needs including those of low-cost, fast turnaround, blue, food contact components.

The co-located events

As mentioned at the beginning of the article there is a whole host of related activities and attractions taking place during Smart Manufacturing & Engineering Week. Central to SM&E Week are the exhibitions, of which there are three taking place in Hall 4. Of great importance to H&P readers is the newly invigorated Maintec, the UK’s longest standing exhibition dedicated to the maintenance, reliability and asset management industry. Maintec has its own education theatre and the ability for visitors to access the major maintenance, repair and operations product and service suppliers as well as all the other content taking place makes the event more relevant for visitors and has brought it to life. To ensure that visitors access the information they want there will also be a ‘Maintenance Safety Trail’ which visitors can follow to ensure they see the right businesses and technologies dedicated to ensuring maintenance is conducted safely.

Also in hall 4 is Smart Factory Expo which is designed to allow manufacturers to be the most efficient, the most sustainable, and the most profitable in the world and where visitors can find the insights, the solutions, and the connections for their digital transformation projects. Similarly to Maintec a ‘Cyber Zone Trail’ will be part of the exhibition directing visitors to the technologies and solutions that address cyber threats and the real threat of cyber-attack that manufacturers and other large scale digitally focused businesses face.

The Design & Engineering Expo is also in Hall 4 and, as so much at the event, it focuses on innovation so that design and engineering professionals who want to reduce costs, streamline and optimise future design and engineering strategy can find what they need.

A major addition to SM&E Week in 2024 are the exhibitions taking place in Hall 5. Pre-registration ensures seamless access to all the exhibitions mentioned in this article with a single badge and for 2024 this includes Drives & Controls, Fluid Power & Systems and Air-Tech. Drives & Controls has always been a major exhibition and this year it will be enhanced by being part of SMEW. Drives and Controls traditionally brings together suppliers of state-of-the-art equipment covering critical areas such as energy efficiency, machine safety, drives, motors, motion control, robotics and automation and much more.

Alongside Drives & Controls in Hall 5 is the Fluid Power & Systems exhibition that focuses on hydraulic and pneumatic equipment for the industrial and mobile markets. Endorsed by the British Fluid Power Association, the BFPA will also have a stand to meet with its members to discuss their education, training and other needs. As well as this the BFPA will be presenting several sessions in the Fluid Power & Systems educational theatre. Finally, in Hall 5, the Air Tech exhibition focuses on the compressed air, generator and vacuum markets.

As well as the events mentioned in this article taking place at the NEC at the same time are other relevant events including the UK Garage & Bodyshop event run by Messe Frankfurt; Med-Tech Innovation Expo and TCT 3Sixty from Rapid News Group and Subcon from the Mark Allen Group.

Bring the noise

In addition, one of the most popular “festival style” attractions of SM&E Week returns in 2024 – the Guitar Legends Competition. Entrants get the opportunity to play and record a piece of music (an intro, brilliant riff or a whole song) and entries are then judged by a professional musician.

On the theme of music and fun, the Day 1 after-show party will welcome visitors and exhibitors alike. It gives everyone the chance to relax after a busy day and to be entertained by the the Shadow Monkeys band, who play a mix of up-to-date dancefloor hits and classic rock tunes. It will help to prolong that festival vibe.

For more entertainment, and continuing the theme of refreshment, more energetic visitors will be able to power the production of their own smoothie via a bike challenge and perhaps to consume it while drinking in the Best of British showcase – a celebration of domestic manufacturing, featuring world-beating designs, innovative modes of manufacture, products that redefine categories, and export successes that have planted the British flag in overseas markets.

With all the fun and worthwhile activities taking place on the fringe, it’s important to know that this year, Smart Manufacturing & Engineering Week will maintain its carbon-neutral status, having planted more than 20,000 trees in the Nineteen Group Forest since 2022. Enginuity is also contributing to the fight against climate change by offsetting 59 tonnes of carbon dioxide, achieving this by supporting a global portfolio of verified carbon reduction projects via Carbon Footprint. Plus, with an eye to the future, the event’s charity partner is once again Engineers Without Borders UK, which works with young people, students and those working in industry, to ensure that globally responsible engineering is embedded in the thinking of both engineers and the businesses they work for.

With so much going on during Smart Manufacturing & Engineering Week the organisers will be creating ‘visitor trails’ to help attendees tailor their experience to their own areas of interest.

SHOW FACTS

Where: NEC, Birmingham

When: 5–6 June, 2024

Opening times:

Wednesday 5 June 2024

09:30-17:00 Exhibition

10:00-16:00 Content Sessions

Thursday 6 June 2024

09:30-16:00 Exhibition

10:00-16:00 Content Sessions

Entry: Free (register at: https://fluid-power-systems-2024.reg.buzz

https://www.linkedin.com/showcase/smart-manufacturing-engineering-week/