TI Live delivers successful learning experience

Published: 20 July, 2023

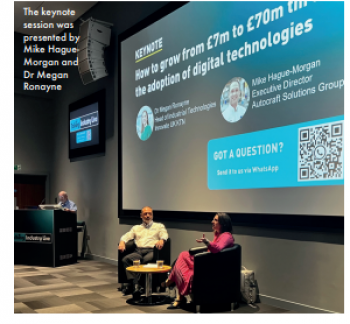

The inaugural Talking Industry Live conference took place at the MTC on 25 April. Moving from its on-line format to a physical version, the event started with a keynote session dedicated to a case study in digital transformation, followed by three themed discussions. Chair Andy Pye takes a look back over the day.

Talking Industry Live began with a keynote session entitled How to grow from £7m to £70m through the adoption of digital technologies. Unusually, it comprised a double-act – a discussion between Mike Hague-Morgan, executive director of Autocraft Solutions Group, and Dr Megan Ronayne, head of industrial technologies and manufacturing at Innovate UK KTN.

The KTN and the Catapult network played a vital role in Autocraft’s digital journey from being a traditional manufacturer using hand tools and paper-based systems, to a high-tech company with world-class quality, repeatability and digital traceability. The change has been the catalyst for its turnover climbing from £7m to £70m.

Hague-Morgan explained that he started his journey in manufacturing, working at Ford. By 26, he had been promoted to commercial director in a large multinational company and, due to the decline in some areas of manufacturing, had become something of an expert in consolidating sites and downsizing businesses!

In 2007, he was headhunted to join Autocraft Solutions Group (ASG), owned by US-based ATC Drivetrain. This traditional business had been profitable in the late 1990s, but turnover had dropped from £20m to £7m and it was losing £1m a year.

Hague-Morgan explained: “ASG had not won a contract in five years and consolidated from over 200 people to 98.

“At this time, engines were unreliable and there were lots of businesses like ASG. There was consolidation of the industry, and I was brought to ASG to manage the consolidation, to the point that ASG would be the last engine remanufacturer business remaining in the UK.”

He was given 18 months to turn it around, but 12 months in, the American owners decided to close it. Hague-Morgan decided to buy the business. “I had 98 workers to think about and keep their jobs, with multigenerations of families working for this business.” He had just four weeks to get the money to buy the business. He and two partners needed to find £500,000 and £150,000 of their own money, which they would lose if it went wrong. He used a lump sum from his mother’s pension to buy the shares.

Happily, his instincts proved correct and he managed to save the business and double its turnover to £14m, returning the money he had borrowed in a relatively short time.

The digital revolution

By 2015, a big step-change in engine technology was underway, both on emissions and efficiency. Remanufacturing increased, so Autocraft had to ramp up without having the money to invest. At the time, the company was still relying on hand tools, lots of paperwork and a lack of traceability.

At the same time, talk was starting about Industry 4.0 – the digitalisation of the manufacturing sector. Businesses were starting to record data for traceability and productivity improvements.

In 2017, digital adoption and the importance of digital technologies were ramped up with the Made Smarter Review, led by former Siemens CEO Juergen Maier and Innovate UK KTN’s manufacturing team.

Hague-Morgan started to attend KTN events and learned from lots of different factories and manufacturing environments. In 2017, he was invited to a KTN workshop at the Catapult, which was trying to get companies to invest in digital technologies. Tentative steps into computer vision followed, when the company bought its first robot and camera, which it integrated and programmed in-house.

Hague-Morgan met a student who wrote computer games and programmed vision systems. From there, ASG partnered with a small business to build a camera-controlled assembly system. This development cut training from six months to two weeks, and the company started to sell to third-party customers.

These small steps in adopting technology resulted in 70% growth over an 18-month period. It improved the quality and traceability and production processes and started to develop confidence in digital skills.

Between 2015 and 2020, ASG grew to £40m turnover and developed a “Library of Digital Capability”, taking small accessible elements of technology and starting to integrate them.

“I could never have had done this without Innovate UK and the 60/40 match funding, which as an SME was absolutely vital,” HagueMorgan concluded. “KTN was vital to bring together universities, the Catapult network, and in providing guidance of where to get the right help at the right time. We haven’t invented any of these ideas, but benefitted from being exposed to a range of technologies which we have been able to adapt to our own environment.”

Some of the key lessons that Hague-Morgan learnt included:

Start small with digital adoption;

For SMEs, integrating different digital technologies is powerful and gamechanging;

A key barrier to digitalisation is skills and the culture towards change;

When recruiting, look at the hobbies and interests of people outside their work;

Put young people together with experienced engineers and knowledge transfer will occur in both directions!

Podcasts of the Talking Industry Live sessions are available from https://talkingindustry.org/podcast and major podcast sites. Talking Industry Live will return next spring.

https://twitter.com/TalkingIndustry

https://www.linkedin.com/company/talking-industry/