New inverter kit speeds up setup and simplifies maintenance

Published: 06 July, 2023

Mitsubishi Electric has released a 24VDC digital input plug-in module for its FR-E800 range of variable speed drives (VSDs). PWE takes a closer look.

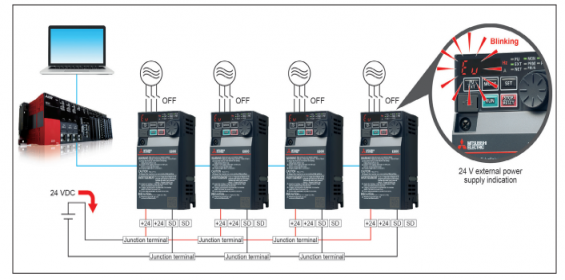

Developed to support setup and maintenance activities, the FR-E8DS keeps the node active when the main power source is turned off. This improves flexibility and reduces energy requirements whilst enabling users to interact with the control section without the need for an industrial power supply.

Easy to add to FR-E800 drives, the FR-E8DS module offers a tool to leverage a low voltage supply in order keep core functions available when power from the mains is removed from the VSD. More precisely, the operation panel remains active, as do Ethernet and RS-485 communications between the VSD and other devices. Also, the unit can turn on and off any I/O terminals linked to the drive.

Maintenance can therefore be performed effectively and without the need for more demanding 200V or 400V energy sources, which are typically used to power VSDs. By leveraging this kit, drive availability is optimised, as parameter setting and communication operations can be quickly carried out, even when the device is removed from its application. Operators can also interrogate the inverter from the PLC and parameterise it.

Wayne Turtill, Product Manager Drives & LVS at Mitsubishi Electric, explained: “You generally need 200V or 400V to power a drive, even in standby mode. The new solution allows you to plug a 24V power supply into the drive and turn off the mains connection. The supply keeps the control electronics and networks alive inside the drive. When inspecting an inverter, it means that you can set this drive up on your desk without requiring a 400 V or 200 V power supply that may not be accessible.”

Even more, the FR-E8DS kit also facilitates troubleshooting. Once connected, if a fault occurs, its indication remains active even when the drive is removed from the main power supply. Once diagnostics and maintenance activities have been completed, reconnecting FR-E800 units is straightforward, as turning on the main circuit power whilst the 24V external power supply is active switches the operation to ‘normal’ mode.

The FR-E8DS module comes with two front cover options for installation within the FR-E800 unit. More precisely, in place of the standard plug-in option, users can use a smaller alternative if there is limited room available. Connectors, spacers and screws are also included in the kit to provide a complete solution.

Wayne Turtill concluded: “Offering value-adding solutions to our customers is our top priority. This is why we continue to invest in the development of new technologies that can improve maintenance, reliability and energy efficiency. Our latest FR-E8DS E-kit addresses these goals, greatly benefitting FR-E800 users. By leveraging it, customers can maximise the effectiveness of their drives and the processes they support, as well as any activity to improve overall operational performance.”

https://www.linkedin.com/company/mitsubishi-electric-living-environmental-systems-uk_2/