You do get what you pay for

Published: 18 January, 2023

When it comes to power transmission chain, Tsubaki told PWE that buying a quality product results in significant life-time cost savings.

The climate in most industries at the moment is focussed on cost reduction to protect margins. While this is a noble pursuit, and one that can offer real benefits to a business and its customers, it is important that when it comes to procurement the Total Cost of Ownership (TCO) is considered over initial cost savings. While some components may seem like the cheapest solution in the short term, they can quickly prove expensive if regular maintenance, repair, and replacement work becomes necessary.

Power transmission chain manufacturer, Tsubakimoto, believes that the key to real world cost savings lies in an extended, low maintenance, operating cycle.

All too often when we hear about a business cutting its costs, we hear in the same sentence that the cuts have been achieved by sourcing cheaper components during procurement. However, while these savings may look appealing in the short term, the only real way to gauge success is to look at the total cost of the product throughout its life. Cost of installation, maintenance requirements, downtime caused by early failure and replacement are all hidden costs which can add up when a budget component is specified.

Power transmission chain in particular is an area where many procurement managers may feel they can reduce costs by specifying budget chains. Because the technology is apparently so simple, and there are few outward differences in appearance between brands, it would be easy to assume that this is an area where budget components may be justified. However, the truth is very different; a chain which has been properly specified and well produced, using high quality materials, can often earn its initial procurement cost back many times over when compared with cheap chain.

Jake Yamamoto, Sales & Marketing Director for Tsubakimoto Europe, commented: “Initial procurement is just one cost that needs to be considered when determining the TCO of power transmission chain. After procurement there is installation time, which can vary greatly between products, as well as the necessary maintenance requirements – such as lubrication or removing links due to elongation. Then of course there is the cost of replacement. A chain with a shorter life will need replacing which not only causes down time but also introduces a further round of procurement into the equation. When all of these hidden costs are taken into consideration it is easy to see how budget chain can quickly become a false economy.”

The ability for a premium chain to offer significant TCO savings has been experienced first-hand by a food producer who was looking for an alternative roller chain solution for it cake production line. The basic 12B chain that it specified as standard had an average life span of 9 months despite regular maintenance. The plant’s management was concerned about the regular replacement costs and approached Tsubaki to see if an alternative solution could be provided.

Having conducted a site inspection, the Tsubaki engineer specified Lambda lube-free chain. The innovative Lambda chain does not require any external lubrication, which gives an instant maintenance cost saving As the chain surface is dry, any contamination risk is avoided. The chain bearing surfaces remain lubricated, which minimises wear and offers a much longer operating life.

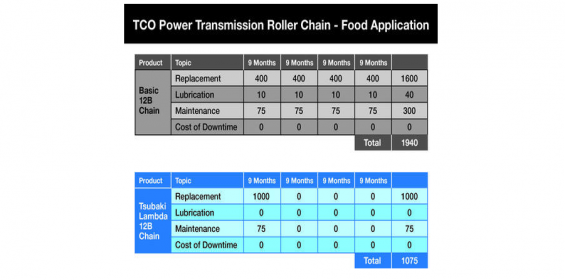

The procurement cost for a single length of Lambda chain was almost 150% more than the cost for the basic 12B chain – which may have put a lot of operators off. However, once installed, the chain lasted for 40 months without the need for any maintenance. Over 40 months the basic chain would have been replaced four times and accrued regular maintenance costs. As such the Lambda chain was almost 45% cheaper to run which represented a saving as shown in the table in the image

If you take into account lubrication and replacement maintenance time, then the TCO figure starts to look more realistic, and closer to 100% more expensive. This is also without adding any potential downtime costs. The chain is replaced during a routine maintenance window, then there is no figure there, but, if the plant could be up and running instead of being stopped while the roller chain is replaced then the cost per hour of lost production can easily run into thousands.

Yamamoto continued: “Tsubaki invests heavily in R&D and offers a wide range of products which have been designed for all types of industries and environments. This means that for most applications, even traditional hardwearing ones, we are able to specify a solution which will last many timeslonger than a basic chain. We will conduct a site visit prior to specification to make sure that we understand the unique requirements of every job so that we can provide an accurate estimate for our chain’s TCO.”

https://www.linkedin.com/company/tsubakimoto-uk-ltd/

Cost saving comparison table showing the difference between a Standard chain and a Tsubaki Lambda Lube-free chain