Maximum safety for load turning

Published: 30 November, 2020

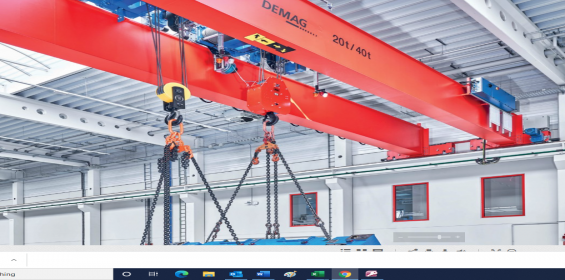

Material handling specialist, Demag, has introduced a new load turning function for its universal crane product range. The load turning capability achieves maximum safety and significant operational advantages, without the need for potentially costly additional engineering features. The Demag SafeControl safety control unit monitors the entire load turning process. PWE reports.

Many users of indoor cranes are faced frequently with the complex task of not only lifting and horizontally moving heavy components, such as press tools, machine beds or special containers, but also turning these loads.

Although this function has been possible with Demag cranes for decades, it required additional engineering features. The manufacturer has now simplified and standardised the load turning function, with universal cranes and two hoists delivering the highest levels of safety, while eliminating the need for the same level of supplementary engineering work previously required. As a result, the crane operator benefits from a costeffective solution, which demonstrates functionality, high productivity and inherent safety.

The package of features enabling the load turning function includes more generous specification of the steel structure and the equipment incorporates extra sensors. In addition, the Demag SafeControl system, which provides safety-orientated control and monitoring of all crane motions and functions, has been modified specifically for the load turning process.

Depending on the requirements for the capacity of the rope hoists, an inclined angle of pull of up to 20 degrees can be achieved, allowing loads of up to 50 t to be turned. The user can choose between two versions, both of which are intrinsically safe. Precise measurement of the rope angle is achieved by combining the Demag SafeControl system with a two-channel, non-contact sensor system. The basic version provides an acoustic and visual warning as soon as the maximum rope angle deflection is reached.

In an alternative configuration, the Demag SafeControl system monitors all motion sequences for safe operation and automatically stops lifting and travel motions if the maximum permissible rope angle is exceeded. This helps achieve a high safety category of Performance Level d (lifting) or c (travelling) to EN 13849-1, category 3.

On both variants, the load turning function is wirelessly operated via joystick transmitters as standard, allowing intuitive control while closely watching the load to be turned. Alternatively, control is also possible with hand-held button transmitters or hand-held transmitters with minijoystick operation.

Demag’s Director, Industrial Cranes, UK sales & operations, Paul Bartlett, commented: “The new load turning function offers a simple, efficient and safe solution for crane users involved in complex material handling applications. The facility will be attractive to a wide range of operators requiring specialist lifting and moving techniques. The introduction of this feature within our portfolio of universal cranes demonstrates our commitment to material handling innovation and providing customers with answers to specific requirements.”

https://twitter.com/demagcranes

https://www.linkedin.com/company/demag-cranes-&-components/?viewAsMember=true