Pumps and Valves: New normals, new challenges

Published: 02 July, 2020

While end users in the process industries began to digitise their plants decades ago with the introduction of “smart/intelligent,” digitally integrated process transmitters and final control devices, pumps and valves have often been last in the queue. Andy Pye, consultant editor for PWE, reports.

The ability for smart valves and pumps to improve process performance, condition monitoring and maintenance effectiveness is substantial. Advanced diagnostics and bidirectional communications can also improve environmental compliance and plant safety.

In the post-CoVID world, this trend will accelerate, as maintenance managers in manufacturing plants may have to operate under lockdown and service engineers may experience difficulties in undertaking regular visits to client premises.

Advanced pump controller

On the smart factory shop floor, pumps are increasingly required to supply real-time operating data so that their performance can be monitored and adjusted. Torque is one key performance indicator: a gradual increase in pump torque may suggest increasing flow to compensate for growing leakage; a sudden increase may indicate a blockage downstream of the pump, while a sudden reduction may be due to an upstream blockage.

One difficulty is how to connect torque sensors to equipment such as pumps, mixers and conveyors. Wiring up one machine using a delicate slip ring is quite feasible, but in a highly automated factory may have hundreds or thousands, so the task becomes untenable. An alternative approach is to use a non-contact radio frequency detector. Sensor Technology’s new Bluetooth module is a totally wireless approach to torque measurement. The TorqSense is a wireless sensor that replaces physical wiring and slip rings with radio wave communications. It can be used with virtually all pump-based systems, from microdosing of active ingredients in pharmaceutical production. Fitting a TorqSense typically takes about one-fifth the time required for a conventional hard-wired transducer.

A virtual valve repair service

Depending on the criticality and the application, established maintenance plans can vary from daily monitoring to less-frequent inspections and repairs. Ensuring valves meet operational standards requires detailed record-keeping and right-skilled talent to oversee the repair.

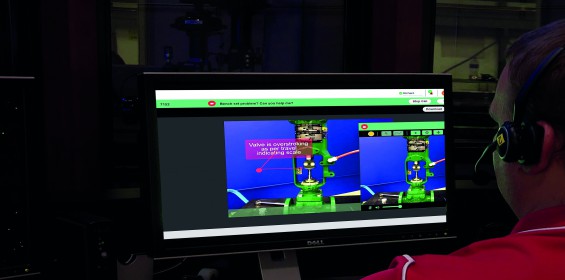

Now, to help plant operators respond to urgent issues, Emerson has launched a Remote Assistance service which uses augmented reality (AR) to facilitate real-time repair. Using a mobile device, plant personnel can securely share their field of view through the AR software, enabling Emerson’s valve engineers troubleshoot and solve the problem. Step-by-step instructions are overlaid in the field-user’s application to support installation, calibration or repair actions.

“Our customers are supporting critical infrastructure through the global health crisis that we’re experiencing, but they still encounter issues where they need outside help," says Clint Schneider, director of Emerson’s digital valve services. "Through the use of this technology, we are able to continue our promise of support while protecting essential on-site staff and Emerson technicians."

Taking the heat out of cell cultures

Peristaltic pumps also play a critical part in the bioreactors working flat out to manufacture a range of vaccines in sufficient volume to defeat the pandemic. In one application, the pump has internal tubing that separates media from pump components and offers a sanitary method to supply the bioreactor with various fluids to grow cell cultures in the development of new medicines. Stepper motors drive the pump head, compressing and releasing the pump tubing to move media into the bioreactor chamber.

To remove excessive heat in, its open-loop stepper motors have been replaced with their closed-loop counterparts. The excessive heat elevated the temperature of fluids being pumped into the bioreactor, which adversely affected processing times and reduced yields. By incorporating encoder feedback and servo-control firmware in Applied Motion Products' closed-loop steppers, the current is controlled to meet torque demands precisely. This eliminated the heat problem by operating less hot and consuming less power.

X-ray systems spots food contaminants

Although there is currently no evidence that the novel coronavirus can be transmitted via food, transmission via surfaces recently contaminated with viruses is, nonetheless, believed possible through smear infections.

Sparc Systems has designed the Iris pipeline X-ray system to detect contaminants in vacuum filled and pumped meat, poultry and dairy products.

Iris will identify many different physical hazards, including bones, teeth, metal, glass, ceramics, and high-density plastic in muscle meats, slurries, semi solids, and fluids. The X-ray sensor can detect foreign materials with high sensitivity levels down to 0.4mm.

Any product shown to contain contaminant is shown on a display screen and immediately rejected from the system before it is transferred downstream.

The Iris features a three-way electric valve that allows test pieces to be inserted into the product flow to provide a true performance reading. For fast set up and ease of use across mixed product lines, it can easily be integrated into an existing rigid or flexible piping system or placed behind a vacuum filling machine.

Piezo proportional flow control valve

A new VEMD proportional flow control valve from Festo is targeting applications in life sciences and mobile applications, ranging from ventilators and anaesthesia to operating equipment for ophthalmology and dental drills. It uses the latest piezo technology to deliver highly dynamic control for medical and industrial control applications. The valve integrates a flow sensor with a proportional valve and controller for regulating the flow of compressed air or inert gases, up to 20 l/m at a maximum pressure of 2.5 bar.

In operation, it compares the required signal value with the actual, sensor-measured value within its closed loop electronic controller and then adjusts the output using a piezo pilot valve. The pilot valve features low heat generation, long service life, power consumption of only 1W and silent operation, ideal for patients who are bed bound and need rest uninterrupted by noisy solenoids.

Green mining from the tail up

Driven by increasing scarcity of water, the mining industry is seeking sustainable strategies to address rising risks, costs and compliances. The way increasing volumes of mine tailings are handled can have a long-term impact on a mine’s economic efficiency as well as on the surrounding environment and communities. Dewatering of this waste allows water removal and its reuse, either in the plant itself or restoration to nature.

Suitable dewatering technologies range from lamellar thickeners, hydrocyclones and filters to tailings stackers, including pumping and conveyor belts. Metso has launched its VPX filter for tailings dewatering. It is designed to maximize water recovery and reduce the footprint of tailings dams or eliminate them completely.

At Metso's facilities in Sorocaba, Brazil, the first full-scale tests of the Metso VPX filter started in March 2020. The unit is processing ore samples sent by several mining companies from Brazil and Latin America. "This is not a laboratory test, but filtration in industrial scale conditions using VPX technology, which has the capacity to process high volumes of ores", says Rodrigo Gouveia, Vice President, Tailings Management Systems, Metso.