Ultrasound monitoring

Published: 25 September, 2019

Airborne and structure-borne ultrasound is a technology that has been around for more than 50 years. In the technology’s early days, the main application was compressed air leak detection. Even today, that is still the most widely used application for airborne ultrasound. Advancements in leak detection using ultrasound have come by way of reporting and documenting the air leaks that are found. The reports quantify the air leaks by showing the cost and CFM loss related with the air leak. UE Systems’ Adrian Messer, CMRP, reports.

Over the years, through advancements in both ultrasound instrumentation and software, more maintenance and reliability personnel have begun to use ultrasound technology for more than just compressed air leak detection. Three applications in particular have seen a large increase in usage: condition monitoring of bearings and rotating equipment, condition based lubrication using ultrasound, and electrical inspection of energised electrical equipment.

What is ultrasound?

Ultrasonic equipment detects airborne and structure-borne ultrasounds normally inaudible to the human ear and electronically “transposes” them into audible signals that a technician can hear through headphones and view on a display panel as a dB level. On some instruments, incoming sound can also be viewed on a spectral analysis screen which shows either the FFT or Time Wave Form. With this information, a trained technician can interpret the bearing condition in order to determine what, if any, corrective action is needed, and the current data can be compared on the spot to the baseline data.

Ultrasound technology has many advantages:

• It can be used in virtually any environment.

• Learning to use ultrasound technology is relatively easy.

• The technology is relatively inexpensive.

• Modern ultrasonic equipment makes it easy to track trends and store historical data.

• Ultrasonic technology has proven itself to be extremely reliable in predictive maintenance, saving thousands upon thousands of dollars and hours of lost productivity.

• There are remote monitoring options for both mechanical and electrical applications.

Airborne and structure-borne ultrasound instruments are an extension of the user’s sense of hearing. Similar in that vibration feels what you can’t feel and infrared cameras see what you can’t see, ultrasound hears what you can’t hear. There are sounds taking place in a typical plant and manufacturing environment (machines running, production equipment running, etc.) that prevent us from hearing other sounds such as compressed air leaks, or electrical discharges like corona, tracking, or arcing. Ultrasound instruments listen for sounds that are not present in our normal audible range.

Typically, the sounds outside normal human hearing are high frequency sounds. The high frequency sounds are detected by the instrument and translated through a process called heterodyning into an audible sound that is heard in the headset by the inspector. The unit of measurement for sound is a dB level which is indicated on the display of the ultrasound instrument.

Why remote monitoring with ultrasound?

Remote monitoring with vibration analysis and temperature has been available for many years. For ultrasound, it’s a fairly new addition to the technology’s repertoire of capabilities. When considering adding ultrasound to your condition monitoring programme, the decision ultimately depends on what assets you would like to monitor. Once you have determined the assets that you would like to monitor, you need to identify the failure modes related to those assets. Understanding how those assets will fail will help you to determine which condition monitoring tool can be applied to find those failure modes.

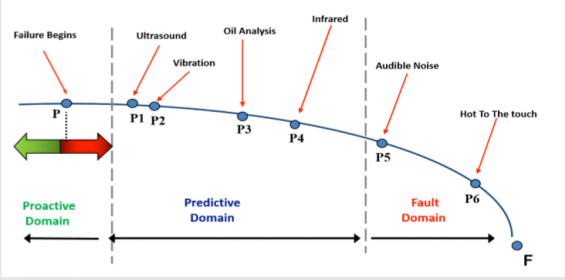

Ultrasound is a proven technology that can detect certain mechanical and electrical faults much sooner than other technologies. By sensing subtle changes in ultrasonic amplitude, ultrasound is adept at finding early stage premature bearing faults.

Ultrasound plays a critical role in helping to extend the life of bearings in the I-P interval by condition lubrication of bearings. Studies have shown that the majority of premature bearing failures can be attributed to lubrication. Whether it’s over-lubrication, under-lubrication, using the wrong grease for the wrong application, mixing incompatible greases, or lubricant contamination, all of it comes back to improper grease application. Ultrasound can prevent over- and under-lubrication, thus potentially eliminating a large number of bearing failures.

When a bearing lacks lubrication, there is an increase in friction. The higher friction also increases how much ultrasonic noise the bearing produces, indicated by a rise in the decibel (dB) level. While greasing a bearing that is need of lubrication, one should see a gradual decrease in the dB level. Once the dB level has fallen back to a normal or baseline level, greasing can be ceased. If the bearing already has a sufficient amount of grease when greasing, then the dB level will slowly begin to rise as more grease is applied. That’s because over-lubrication also increases friction in the bearing housing, thus producing a higher dB level. The inspector would notice the rise in dBs as grease is applied and would stop greasing.

In the P-F interval once a failure has begun, ultrasound is excellent at finding it. These are bearing failures that can be detected even before changes in vibration. If you’re monitoring critical assets, ultrasound and vibration should be used together in an effort to potentially detect multiple failure modes that may be missed when only using one technology alone.

Viable option

Remote monitoring with ultrasound is a viable option for maintenance and reliability programmes that are already monitoring assets traditionally with hand-held devices, and for programs where ultrasound is currently not a technology that is being used. Because it is very complimentary to vibration analysis for mechanical inspection and infrared thermography for electrical inspection, ultrasound will only enhance condition monitoring efforts already in use. Using ultrasound for mechanical and electrical inspection will deliver an increased level of monitoring for critical assets and assets that are currently not being monitored with vibration analysis or other condition monitoring technologies. Anywhere you would consider using traditional data collection techniques, remote monitoring can be a viable option as well. In areas that are inaccessible, dangerous, or remote, remote monitoring with ultrasound may be your only option. Additionally, a multi-technology approach to condition monitoring increases your chances of finding multiple failure modes and detecting them early enough to make the necessary repairs before they become catastrophic.

I-P-F Curve showing ultrasound as an early indicator of a potential problem in bearings and rotating equipment.

For further information please visit: www.uesystems.com

QUANTITECH has announced that the Gasmet CEMS II e continuous emissions monitoring system has successfully completed EN 15267-3 testing using FTIR technology for the analysis of low range HF, low range NO, CH4 and Formaldehyde. “This means that it meets the performance specifications for a larger number of components than any other FTIR in this market,” commented Quantitech MD Ken Roberts.

QUANTITECH has announced that the Gasmet CEMS II e continuous emissions monitoring system has successfully completed EN 15267-3 testing using FTIR technology for the analysis of low range HF, low range NO, CH4 and Formaldehyde. “This means that it meets the performance specifications for a larger number of components than any other FTIR in this market,” commented Quantitech MD Ken Roberts.