Advancing monitoring and diagnostics

Published: 30 August, 2023

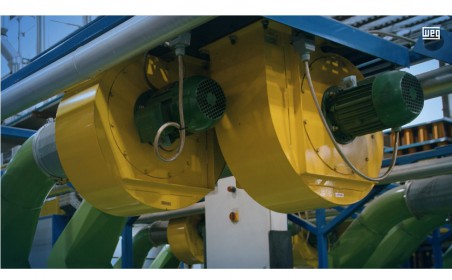

Monitoring the condition of large industrial equipment fleets is challenging and, without the necessary insights, it can be hard to understand the health and performance of assets. To help operators overcome this challenge, industrial digital solutions provider WEG has launched its new WEGscan sensor. By integrating WEGscan into their fleet, operators can monitor a wide range of equipment, including reducers, gear motors and compressors, helping operators reduce costs and improve predictive maintenance.

The new sensor is an evolution of the existing WEG Motor Scan WEGscan and can be integrated onto a range of industrial assets to gather data and feed it to WEG Motion Fleet Management (MFM), a condition-based internet of things (IoT) platform that allows customers to monitor their assets online. Using this technology, users can monitor the operational status of electric motors, compressors, fans, planetary reducers and many other assets on sites across different industrial sectors.

WEGscan can be customised for virtually any asset, and its communication range and capability is far more evolved than previous products.

The new sensor offers a cloud solution, with WEG MFM facilitating data storage, analyses by a technician or specialist, and data processing using AI for autonomous fault diagnosis. Therefore, by combining WEGscan with the platform, businesses can be benefit from a reduction in equipment fleet operating costs, or total cost of ownership, by enhancing condition monitoring and understanding faults early.

Marek Lukaszczyk, European & Middle East Marketing Manager at WEG, explained: “Detecting faults in industrial equipment is one thing, but communicating effectively to understand their impact is another.” He added: “WEGscan is the cutting edge of condition monitoring technology, harnessing the cloud, IoT and AI to provide operators with all the information they need to maintain uptime and avoid costly asset breakdowns.”

“This latest addition builds on the benefits of the WEG Motor Scan, and goes further by monitoring the operational status of everything from gear motors, pumps and exhaust fans to compressors and reducers. The scope of monitoring is greater than ever, making it easier for businesses to make vital operational savings and prevent unplanned downtime.”

For further information please visit: www.weg.net

https://www.linkedin.com/company/weg-emena/